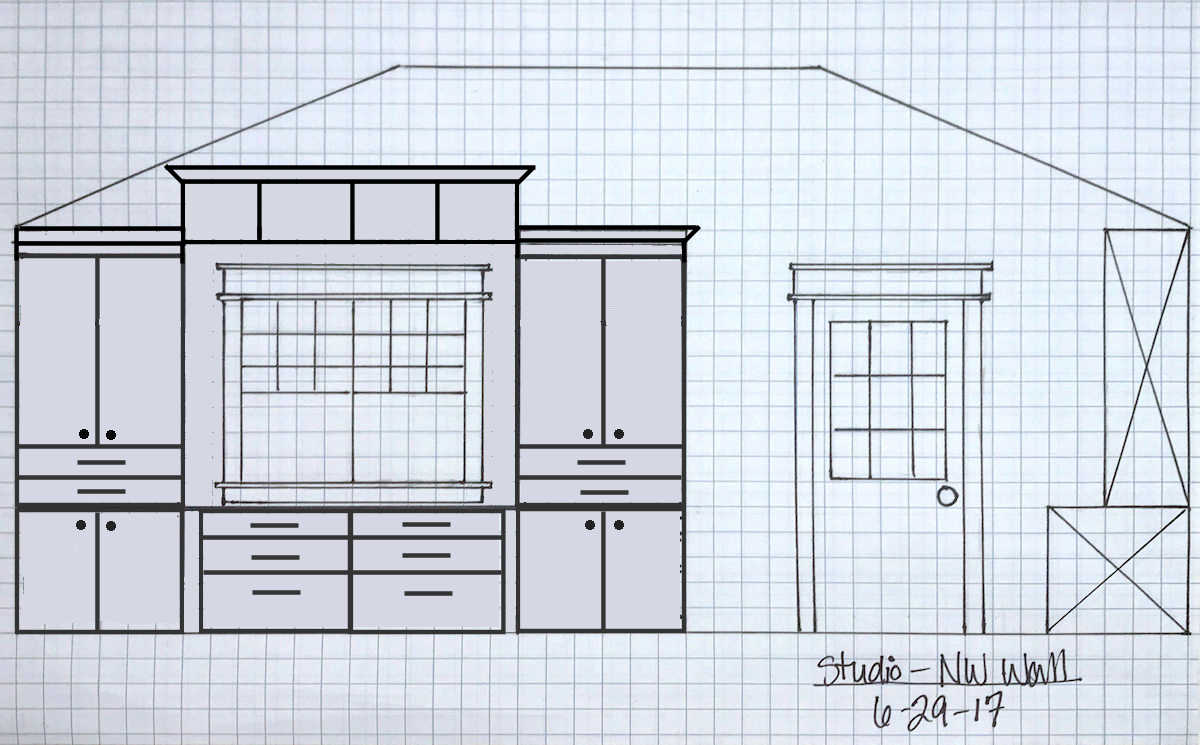

I did it! I constructed the cubby bridge on my studio workplace space cupboards all on my own yesterday, and I couldn’t be extra thrilled with how this part is popping out! As a reminder, right here is the purpose…

And in the beginning of the day yesterday, that is how the cupboards in that space of the room appeared…

The precise cupboards (the white components) are IKEA Sektion cupboards, and I’m within the means of customizing them. This has been a multi-post mission simply getting them up to now, so I’ll hyperlink the earlier posts on the backside of this one.

When it got here to constructing the cubby bridge, my preliminary thought was the construct it within the carport, after which carry it inside and screw it to the perimeters of the cupboards. However I work alone. For many who are new round right here, my husband Matt has M.S. and is utterly unable to assist me with initiatives. And whereas there are a number of individuals who could be keen to come back and assist me, I actually hate to hassle individuals for issues like this. Plus, I’m fiercely unbiased, and I thrive on determining how you can do issues myself.

In order that was the problem. How do I construct a cubby bridge, after which hoist the factor up there on my own whereas attempting to screw it into place? The reply? I DON’T! As an alternative, I made a decision to construct it in place. That appeared like essentially the most “work smarter, not more durable” answer to me. Right here’s how I did it…

First, I measured and marked the place I needed the bridge to be connected to the aspect cupboards, and I connected a bit of scrap wooden to the aspect of the cupboard with the highest fringe of the board alongside the road I simply marked. This ledger board is momentary, and I connected it utilizing three 1.5-inch 16-gauge nails.

After which I repeated that course of on the opposite aspect.

With my momentary ledger boards in place, I measured and reduce a bit of three/4-inch plywood for the underside of the cubby bridge. It took a few tries to get the match excellent, however on the second attempt, it match completely between the aspect cupboards and rested on the ledger boards. You possibly can see that it bows down a little bit bit within the center, however I wasn’t fearful about that. That shall be corrected later within the buiding course of.

After becoming that piece, I eliminated it and drilled three pocket holes on every finish. These pocket holes are on the highest of the board, not the underside. The underside is seen when standing within the room, and I don’t need seen pocket holes, and I don’t like having to fill pocket holes on areas that shall be seen.

To drill the pocket holes, I used my Kreg Pocket Gap Jig. This is the one I have (affiliate hyperlink), and it’s value each penny. If you wish to construct furnishings or cupboards, this device is a must have merchandise!

So once more, I drilled three pocket holes on every finish of that piece, ensuring I drilled the holes on the highest of the piece.

At this level, I introduced my scaffolding in to make the entire constructing course of a lot simpler. This is the one I have (affiliate hyperlink — additionally out there at House Depot), and it’s yet one more factor I purchased not too long ago that I’m wondering how I lived with out for thus lengthy!

So standing on the scaffolding, I positioned the plywood piece again on the momentary ledger boards, pocket holes dealing with up, and I screwed the piece into the aspect of the tall cupboards.

With that secured in place, it appeared like this. The bow within the center was nonetheless there, however I wasn’t fearful about it at this level. I simply needed to ensure that it appeared stage with the trim on the prime of the window.

As soon as I used to be positive it appeared stage, I eliminated the momentary ledger boards. That did depart three nail holes on both sides that I’ll should fill and sand, however I’m okay with that. We DIYers who work alone should do what it takes, and filling and sanding six small nail holes is a small worth to pay for getting this job executed on my own.

Subsequent, I used my desk noticed to chop the items for the ends. I connected these by nailing from the within of this aspect piece into the plywood on the aspect of the aspect cupboard (i.e., within the route my nail gun is pointing beneath).

After which I additionally nailed via the underside plywood piece and into the sting of the aspect piece.

After repeating that on the opposite finish, I used to be prepared to chop the again piece to suit inside the 2 finish items. That is the place the bow in that backside board could be corrected. You possibly can see the again piece set into place beneath, and the bow in that backside board continues to be seen.

To safe that again piece, I first nailed via the aspect items into the sting of the again piece.

After repeating that on the opposite finish, I nailed via the underside piece into the underside fringe of the again piece.

That is what took care of the bow and straightened up the underside plywood piece. You possibly can see that there’s now not a niche between the 2 items at this level.

To be clear, aside from the six pocket screws holding the underside piece in place, I constructed the whole factor utilizing 1.5-inch 16-guage nails. I’ve full confidence that these nails will maintain. The type that go in a nail gun are very tough, and actually seize into the wooden. When you’ve ever constructed something utilizing these nails, and needed to take items aside, you understand how sturdy they’re. However you probably have much less confidence than I do in how effectively the nails will maintain, you may all the time use wooden glue along with the nails, and even add extra pocket holes to carry the items collectively.

Subsequent, I reduce and connected the highest piece, nailing it throughout the three sides that sat on the aspect items and the again piece. I nailed via the highest and into the perimeters of these three items. At this level, it was actually beginning to seem like one thing! 😀

And the ultimate step of the fundamental construct for the cubby bridge was to chop and connect the dividers. I reduce them utilizing my desk noticed, after which connected them identical to the opposite items.

After measuring and marking for placement of those divider items, I nailed via the underside piece into the underside edged of the divider items.

After which I nailed via the highest and into the perimeters of the divider items.

And with that, the fundamental construct was executed! It’s going to take loads of trim and ending to get this part of cupboards to seem like I envision in my thoughts, however I’m effectively on my approach!

I so want that each single considered one of you would see this in particular person. Footage don’t do it justice. This part of cupboards went from trying form of small and dwarfed by that tall, broad wall, to trying very substantial, like it could maintain it’s personal in opposition to that massive wall. Typically, extra is unquestionably higher! 😀 And I believe, when it’s all completed, it should look far more like customized cupboards now.

So keep tuned, as a result of developing subsequent, I’ll get the entire thing trimmed out and prepared for primer and paint. I’m getting actually enthusiastic about seeing this part completed quickly!

Addicted 2 Adorning is the place I share my DIY and adorning journey as I rework and enhance the 1948 fixer higher that my husband, Matt, and I purchased in 2013. Matt has M.S. and is unable to do bodily work, so I do nearly all of the work on the home on my own. You can learn more about me here.